Geofinity - The Real Pain in the Ass for Manufacturing Companies in Nepal — And Why OptERP Is the Game-Changing Alternative

Manufacturing companies in Nepal face constant challenges—manual errors, lack of real-time visibility, inventory chaos, and production delays. Explore how OptERP’s Manufacturing Module solves these bo

Introduction

Let’s be honest:

Running a manufacturing company in Nepal is a real pain in the ass.

Whether you’re in steel, furniture, FMCG, garments, plastics, automobile parts, or food processing—every manufacturer deals with the same headaches:

- Stock mismatches

- Production delays

- Manual record-keeping

- Zero real-time insight

- Miscommunication between departments

- Poor tracking of raw materials

- And… the never-ending Excel sheets 😩

These problems don’t just create stress—they eat profits, waste time, and stunt business growth.

But there is a smarter alternative.

OptERP – Manufacturing, designed by Geofinity Solutions Pvt. Ltd., is built specifically to solve Nepal’s manufacturing challenges with automation, transparency, and real-time intelligence.

Why Manufacturing in Nepal Is Such a Struggle

(The “Pain in the Ass” Problems No One Wants to Admit 👇)

1. Inventory Guesswork

Most factories rely on manual entries or outdated software. Stock-out or overstock is common, causing production chaos.

2. No Real-Time Production Visibility

Managers don’t know what’s happening on the factory floor until it’s too late.

3. Excel Sheet Dependency

From purchase to production to dispatch—everything is done manually. High chance of human error.

4. Slow Decision-Making

Without dashboards or real-time data, decisions take days instead of seconds.

5. Lack of Standardization

Every department has its own way of working. No unified system.

6. Inefficiency and Wastage

Raw material wastage goes unnoticed. Production planning is guess-based, not data-based.

7. Poor Documentation & Compliance

Bill of materials (BOM), work orders, QC documents—maintained separately and inconsistently.

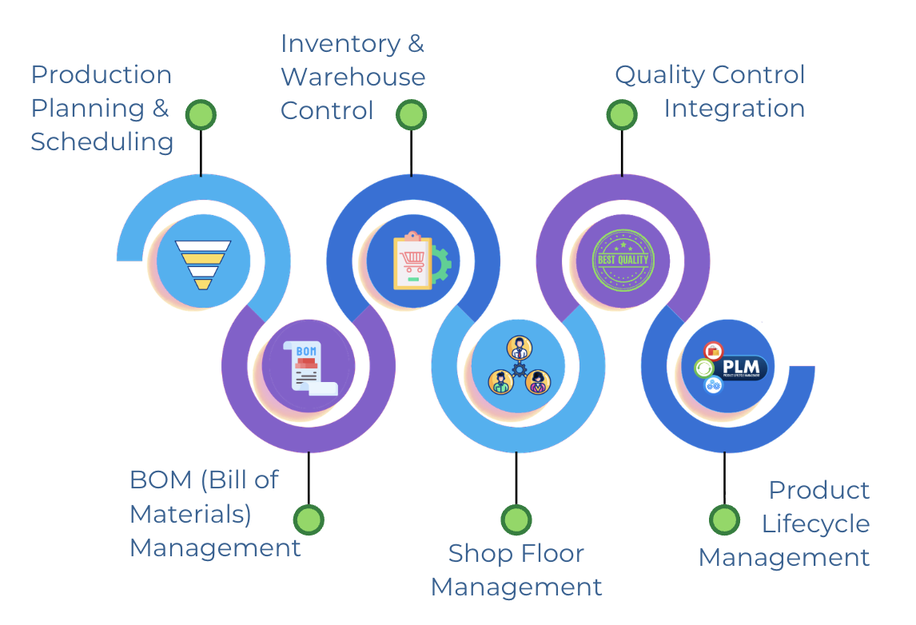

OptERP Manufacturing — The Smarter Alternative

OptERP eliminates all chaos by integrating Purchasing → Inventory → Production → Sales into one connected platform.

It’s built for Nepali manufacturers with:

✔ Nepali tax & billing system

✔ Multi-company & multi-warehouse support

✔ Production planning tools

✔ Real-time insights

✔ Easy usage for staff

✔ Cloud or on-premise deployment

No more Excel confusion.

No more shouting on the factory floor.

No more blind production.

OptERP Manufacturing – End-to-End Process Flow

Below is the clean, streamlined workflow OptERP brings to your manufacturing operations:

1. Material Request (MR)

Production team creates a request for raw materials.

2. Purchase Order / Inventory Check

System checks availability.

If materials are insufficient → Auto RS / PO is recommended.

3. Raw Material Receipt

Materials are received → QC check → Added to stock.

4. Bill of Materials (BOM) Setup

Define exact material, quantity, labor, and operations needed.

5. Work Order Creation

Create work orders with:

- Required materials

- Routing

- Machine/labor scheduling

6. Material Issue to Production

Raw materials are issued automatically based on BOM.

7. Production Execution

Operators update progress via workstation or mobile app.

8. Quality Check (QC)

Inspection of finished goods—accepted or rejected.

9. Finished Goods Stock Update

Accepted items automatically added to warehouse.

10. Packaging & Dispatch

Sales order triggers dispatch management and invoicing.

Benefits of OptERP for Manufacturing Companies in Nepal

✔ 1. 100% Real-Time Visibility

Know what’s happening: inventory, production, machines, and dispatch—all in real time.

✔ 2. Zero Excel Dependency

The entire factory runs through automated digital workflows.

✔ 3. Accurate Inventory & Material Planning

Avoid stockouts and reduce waste with precise tracking.

✔ 4. Cost Control & Waste Reduction

Monitor raw materials, machine hours, and labor to cut production cost.

✔ 5. Improved Production Efficiency

From work orders to routing—everything is organized and trackable.

✔ 6. Quick Executive Decision Making

Dashboards and reports help management take smart decisions instantly.

✔ 7. Better Communication Between Departments

All teams work in one system—reducing miscommunication and delays.

✔ 8. Faster Delivery, Happier Customers

Streamlined production means timely delivery and improved customer satisfaction.

✔ 9. Scalable for Any Size of Manufacturing

From small factories to large industries—OptERP adapts to your growth.

✔ 10. Nepali Support, Nepali Team

On-site support, training, customization, and compliance built for Nepal.

Conclusion

If you’re tired of managing your manufacturing business the old way—

If you’re frustrated with inconsistent data, manual errors, and production confusion—

OptERP is the breakthrough your factory needs.

It’s not just software.

It’s a complete transformation of how manufacturers in Nepal operate.

- Faster.

- Smarter.

- More profitable.

- Zero headaches.

No comments yet. Login to start a new discussion Start a new discussion